Damoiseau expertise

Rum producer for three generations

The cane harvest starts in late January at the earliest and can last up until July. The cane plants are cut into 50-cm lengths with a machine. The fresh cane is delivered to the distillery, where it is chopped up by two shredders. This fiberises the cane stems, which are further shredded and then milled. The juice (vesou in French) is collected at each stage and poured into a tank, where it will be pumped for filtration.

During the second stage – fermentation – the raw material is converted into alcohol by adding yeast. This is when the future rum acquires the characteristics that will give it its identity.

The fermented liquid is then conveyed to the third stage, distillation. When heated, the water separates from the alcohol and the aromatic components it contains. The resultant rum generally has an alcohol by volume in the vicinity of 89%. Before being sold, it will be diluted with water to bring it down to the strength on the bottle (40%, 50% and 55% at Damoiseau).

The rested rum is then pumped to one of the many stainless-steel tanks, where it will be diluted with reverse osmosis water. Despite the dilution, the rum is not yet ready for consumption – its bouquets are not yet being expressed. By placing it in a stainless-steel tank for a few months, the rum is said to become rounder, and its bouquet develops.

Some of our rums are placed in large oak casks for a few months to create gold or amber rums. Our best batches are placed in oak barrels to age for several years, thus obtaining incomparable aged rums.

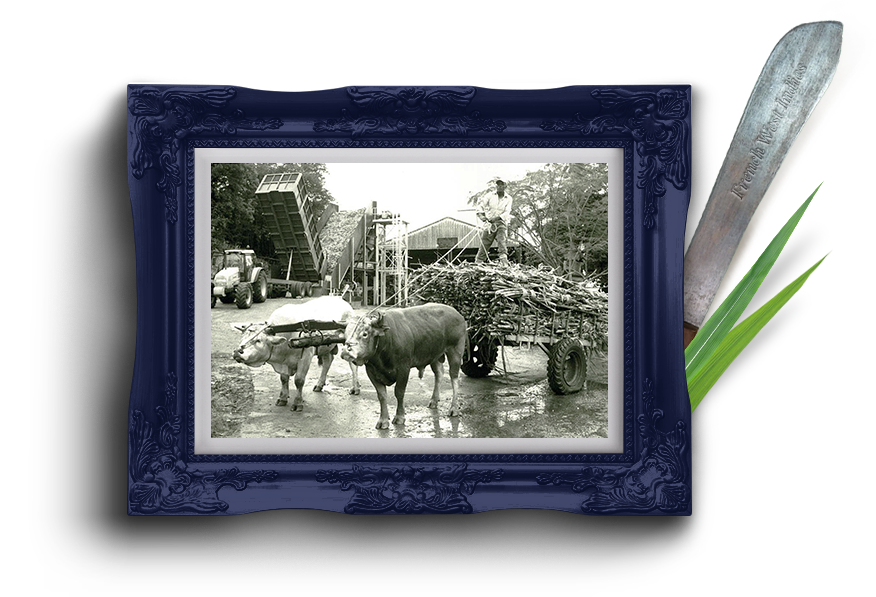

Cutting and pressing sugar cane

Stage one in rum manufacturing

This preliminary stage involves extracting the raw material from the sugar cane. Here, two different methods can be used, giving rise to two major rum categories. The first, known as ‘traditional rum’, is manufactured from molasses, a viscous liquid obtained during sugar refining. The second, known as ‘rhum agricole’ is manufactured from pure cane juice, which is obtained by milling the plant.

Cane harvesting starts around March (depending on the maturity of the cane plants and the weather, it can begin as early as late January), and can last up until July. This is when the sugar cane is cut into 50-cm lengths, then collected by machines. It should be noted that a mature cane plant can measure up to five metres in height. The cut cane should not be left waiting too long before being used. This is why they are usually collected by tractors or trucks, then taken straight to the distilleries or sugar factories.

On receipt, the cane plants are weighed using a weighbridge, then offloaded into a concreted yard. The cane plants are placed on a conveyor belt and conveyed to the shredders, which fiberise the cane stems. This stage is crucial and makes the extraction process considerably easier.

The shredded sugar cane is fed through a series of four roller mills, where significant pressure is exerted (approximately 200 bars.cm-2), which enables the juice to be extracted. This is collected at each stage and poured into a tank, where it will be pumped for filtration. After the second mill, cane juice is obtained on one side and bagasse on the other. This bagasse will be soaked in agricultural water, added to the third mill, so as to dissolve any remaining fermentable sugars in the cane.

Fermentation

Step two in manufacturing rum

During the second stage, that of fermentation, the raw material is converted into alcohol by adding yeast.

This is when the future rum acquires the characteristics that will give it its identity.

Sugar cane naturally contains components that allow for fermentation.

Adding locally grown yeast only accelerates the process.

There are three techniques for initiating fermentation:

Direct seeding : a yeast preparation is introduced to the tanks before they are filled.

Blending : some of the juice in the tank is removed for distillation; the rest is used to seed another tank.

Bottom-of-the-tank : juice left at the bottom of the tank is used to seed a new tank.

‘‘ The Damoiseau distillery mainly uses the bottom-of-the-tank technique. In the event of the yeast potentially becoming damaged, the company chemist uses direct seeding. He would thus add 10 kg of yeast for 500 hl to achieve the desired concentration (0.2g.l-1). ’’

After a fermentation period somewhere between 24 and 36 hours, which can achieve a wine of around 5% ethanol by volume, the chemist tests the density of the wine. If this is between 996 and 999 g.m-3 the wine is pumped and sent to a vat above the distillation columns.

Accelerating gravity helps clarify the wine. The denser yeast falls to the bottom of the tank. It can then be extracted from the wine for distillation, yeast-free. The remainder in the bottom of the tank is used to seed the cane juice.

However, not all the yeast is extracted in this clarification; the small amounts left in the fermentation wine will be destroyed in the distillation process to follow.

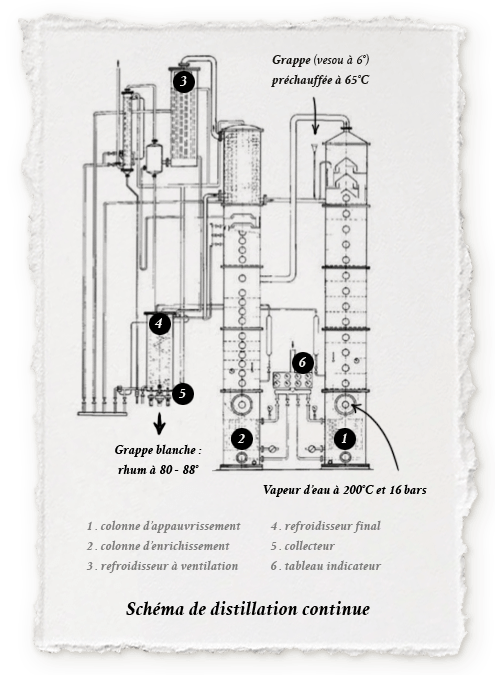

Distillation

Step three in manufacturing rum

The fermented liquid is then conveyed to the third stage, distillation.

When heated, the water separates from the alcohol and the aromatic components it contains.

Generally speaking, distillation is a liquid-liquid separation whose purpose is to isolate a component of a mixture. In this case, we want to isolate the ethanol from the other components in the wine. Distillation uses the fact that each chemical component has a different boiling point to the others.

In our case, we only want rum with an alcohol content of between 80 and 88%, because there is no point producing the purest possible alcohol if you are going to dilute it immediately afterwards. On the contrary, a double-effect distillation reduces the amount of energy needed to achieve the same purity. This is the method used at the Damoiseau distillery.

The resultant rum generally has an alcohol by volume in the vicinity of 89%. Before being sold, it will be diluted with water to bring it down to the strength on the bottle. For example, after distillation, a 30,000-l tank of juice will only produce 2,200 l of rum at 55% vol.

Dilution

Step four in manufacturing rum

After distillation, the 89% rum is stored in big stainless-steel vats so it can rest for several hours.

At this stage, it is not fit for consumption (the alcohol content is too high).

The rested rum is then pumped to one of the many stainless-steel tanks, where it will be slowly diluted with reverse osmosis water.

Despite the dilution, the rum is not yet ready for consumption – its bouquets are not yet being expressed.

It stays in these stainless-steel tanks for a few months (around 90 days).

The rum is said to become rounder, and its bouquet develops.

Ageing

Step five in manufacturing rum

Why leave the rum in casks for years instead of enjoying it right away?

Most of the time, white rum is reduced to an advertised strength, using ‘reverse osmosis’ water.

Time itself also plays a role in aerating the rum, which is why distilleries vary from a few weeks to sometimes several years in the length of time the rum is allowed to rest before being stirred and aerated.

This is the case for rums offered as ‘brut de colonne’ (column strength), for example.

Some rums are placed in oak casks for several months to obtain rums known as élevé sous-bois (matured in wood), ambré (amber), gold or paille (straw). These casks are huge oak barrels that can hold up to several tens of thousands of litres. The rum is allowed to rest in them, which softens it, gives it a little colour and imparts a few woody notes. The amount of rum in contact with the wood is quite small given the volume of liquid, so it is not really referred to as ageing, rather as ‘resting’ or ‘marrying’.

A rum is said to be ‘aged’ after at least three years of ageing. Some designations help us recognise them: VO (Very Old) – aged for a minimum of three years; VSOP (Very Superior Old Pale) – aged for at least four years; and XO (eXtra Old), très vieux or hors d’âge – reserved for an ageing of six years or more.

These extended ageing periods enhance the rums by imparting aromas from the cask itself, but also, and more importantly, by allowing them to develop their own aromas through a multitude of chemical reactions.

Simply being in the cask gives the rum colour, and contact with oxygen results in oxidation, which changes its character. Interaction between the alcohol and the fatty acids in the wood also produces an important phenomenon called esterification,

which develops aromas (aromatic congeners) in addition to those already created during fermentation.

Most of the time, the freshly distilled rum is reduced before being transferred to a cask. If the alcohol content is too high, this attacks the wood and extracts a tremendous amount of tannins. The rum is only transferred to casks once it has reached around 60-70 % alcohol. A high alcohol content apparently extracts more vanillin, whereas a lower strength produces a softer, rounder rum.

Rum loses alcohol during the ageing process. If the cask is placed in a humid, water-saturated atmosphere, alcohol tends to evaporate in larger quantities than water. Conversely, in a dry cellar, the air ‘pumps’ water outside the cask, and the rum may even have a higher alcohol content after its time in the cask than before, as the water-alcohol ratio has changed.

This evaporation (dubbed part des anges in French, meaning ‘the angels’ share’) is substantial in tropical areas, where as much as 8 % can be lost every year, while it is more minimal in Europe with an average of 2 % per year.

The more a cask is partially empty and dry, the more it absorbs liquid, hence the practice of topping up the casks with rums of the same age to minimise evaporation.

Rum also extracts different aromas from the cask depending on its strength: each substance in the wood is soluble at a different alcohol level. It is for this reason that generally, the older the rum, the more complex it is, because it has had access to all the substances the cask could impart, as the alcohol content drops. It is the tannins that degrade first, then the lignins, followed by the hemicelluloses.

‘‘ Ageing is not compulsory, but that is often when the magic happens. That is what gives the rum its rich aromas. ’’